Motion Control Systems for Automation & Robotics

At motec, we design and supply advanced motion control systems that deliver precision, speed, and flexibility. Motion control is essential in today’s automation and robotics industries, ensuring motors, drives, and actuators move in perfect synchronisation. From high-speed packaging lines to multi-axis robotic arms, motion control is the technology that makes complex machine movements possible.

What Is Motion Control?

A motion control system is made up of three key components:

A motion controller to coordinate movement across one or more axes

An interface for the operator, or connectivity through serial communication and fieldbus networks

I/O modules to handle signals, feedback, and system expansion

These elements work together to deliver precise positioning, synchronisation, gearing, speed regulation, and torque control.

Motion Control in Robotics

In robotics, motion control ensures every movement is accurate and repeatable. Robotic arms rely on multi-axis coordination to handle assembly, welding, and pick-and-place operations. With motec’s motion control platforms, you can achieve the precision needed for automation tasks where downtime or inaccuracy is not an option.

Motion Control for Packaging & Manufacturing

In high-speed industries such as packaging, printing, and manufacturing, motion control systems synchronise multiple axes to keep lines running smoothly. From conveyors to cutters, motion controllers guarantee consistent quality and output. Our solutions are designed to meet the demands of both small-scale systems and large, multi-axis installations.

Multi-Axis Motion Control Solutions from motec

motec offers a wide portfolio of motion control technologies, including:

Stand-alone motion controllers for 1 to 64 axes

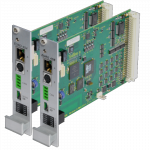

Eurocard and PCI motion control cards for PC-based platforms

Serial interfaces including RS232, RS485, Modbus, and Ethernet

Servo drive integration via EtherCAT

Fieldbus communication through ProfiBUS, DeviceNet, CANopen, Modbus, and ProfiNET

Operator interfaces, I/O expansion, and software tools for complete flexibility

Our scalable platforms can be tailored to suit single-machine projects or large-scale automation systems.

Benefits of Motion Control with motec

Choosing motec as your motion control partner means access to:

Precision – smooth, accurate, and reliable movement across applications

Flexibility – wide compatibility with industrial standards and fieldbus protocols

Scalability – solutions designed to grow with your automation requirements

Expertise – decades of knowledge in automation, robotics, and industrial systems

Start Your Motion Control Project

motec helps you implement the right motion control solution for your application, whether that’s a compact single-axis controller or a complex multi-axis platform.

Explore our products below, learn more about our support services, or contact us today to discuss your motion control requirements.

Human-Machine Interface (HMI)

KeTop HMI Configurator tool

It is now easier than ever to select the perfect KeTop device for you and your workspace. The KeTop HMI

KeTop T20 eco / techno HMI Panels

Never before in mobile operation and teach-in has so much performance been packed into such a compact housing with such

KeTop T150W and T155W wireless HMI touchscreen panels

Our series of the safe wireless products KeTop T150 (portrait version) and T155 (landscape version) combine user experiences from the high-end

KeTop T150 and T155 HMI touchscreen panels

The KeTop series of mobile HMIs from KEBA are the world’s leading solution for mobile operation and teach-in. Machine operators

UniPLAY-A HMI (P561 and P562)

Trio’s unique UniPLAY HMI system is a revolutionary way to make operator interfaces better, easier and more secure! The UniPLAY

Motion Controllers

KEBA’s SAFE remote touchscreen with WinCC Unified

Upgrade your HMI game: Mobile, modern & engineer-approved! We supply top-tier KEBA cabled and wireless SAFE remote touchscreens offering WinCC

KeDrive D5

The successful story of our ServoOne and c-line single-axis series continues with KeDrive D5 and leads us into a new

UniPLAY-A HMI (P561 and P562)

Trio’s unique UniPLAY HMI system is a revolutionary way to make operator interfaces better, easier and more secure! The UniPLAY

UniPLAY HMI (P843 and P844)

Trio’s unique UNIPLAY HMI system is a revolutionary way to make operator interfaces better, easier and more secure! The UNIPLAY

Euro404 / Euro408 (P831, P832, P833 and P834)

The Euro404 and Euro408 Motion Coordinators are designed to provide a powerful yet cost effective control solution for OEM machine

MC403 / MC403Z (P821, P822, P823, P824 and P825)

The MC403 is a high specification Motion Coordinator using a high performance ARM11 processor, with three flexible axis ports and

MC405 (P826 and P827)

The MC405 is a high specification Motion Coordinator using a high performance ARM11 processor, with five flexible axis ports and

MC508 (P848 and P849)

The MC508 is a high specification Motion Coordinator using a high performance ARM Cortex A9 800 Mhz Processor, with eight

MC4N-RTEX (P906, P907, P908, P909, P910)

MC4N-RTEX. It is dedicated to running remote servo drives via Panasonic’s RTEX Real Time EXpress automation bus. It is based

MC664 and MC664X (P891 P862)

The new MC664 single axis core A9 processor. The P861 MC664 Single Core Motion Coordinator is a “drop-in” replacement for

MC6N-ECAT (P960 P961 P962 P963 P964 P965)

The MC6N supports up to 64 axes of motion with 64 bit integer position registers for ultra precise axis resolution.

Flex-6 Nano (P600, P601, P602, P603, P604 and P605)

The Flex-6 Nano is a powerful DIN rail mounted stand-alone flexible and compact Motion Coordinator. Its on board memory can

PC-MCAT 64 (P760)

Trio’s PC-MCAT 64 is an innovative “Motion + PC Solution”. A powerful quad core Intel Atom processor is used to

TRIO – Motion Perfect

Motion Perfect is designed to make setup, diagnostics, commissioning and using our range of Motion Coordinators as simple as possible.

GEL 8240 MotionPLC

With the GEL 8240 cam-plate controller we have combined the Control Panel with the PLC to form a multifunctional compact

IO Expansion modules

FlexSlice Thermocouple module (P367)

The 4 thermocouple inputs are brought out to a single row push-in connector. A second single row push-in connector has

FlexSlice 3 Axis Step Pulse (P375)

The P375 Flexslice 3 Axis Step Pulse Module controls up to 3 Stepper motors with Pulse/Direction/Enable or Pulse/Direction/Registration signals for

FlexSlice 8 Analogue Inputs (P379)

The P379 Flexslice 8 Analogue Input module has eight programmable voltage range input terminals, each digitised to a resolution of

FlexSlice 8 Analogue Outputs (P378)

The P378 Flexslice 8 Analogue Output module has eight programmable voltage range output terminals, each digitised to a resolution of

FlexSlice 16 digital inputs, NPN (P377)

The P377 digital input Flexslice connects 24V dc signals from devices on the machine to the binary control registers in

FlexSlice 16 digital outputs, NPN (P376)

The P376 digital output slice connects the binary control signals from the Motion Coordinator to the machine’s output devices, such

FlexSlice 16 digital inputs, PNP (P372)

The P372 digital input slice connects 24V dc signals from devices on the machine to the binary control registers in

FlexSlice 16 digital outputs, PNP (P371)

The P376 digital output slice connects the binary control signals from the Motion Coordinator to the machine’s output devices, such

FlexSlice EtherCAT IO Coupler (P366)

The Flexslice system begins with the coupler.The coupler is connected to the network via the upper Ethernet interface. The lower

CAN IO – 8 Relay Out (P827)

The Trio CAN8 Relay module offers a compact DIN rail mounted relay output expansion capability for all Trio Motion Coordinators.

CAN IO – 8-in / 4-out Analogue (P826)

The CAN Analogue I/O module offers a compact DIN rail mounted analogue input/output capability for Trio Motion Coordinators. Each module provides

CAN IO – 16-in / out Digital (P319)

The Trio CAN16 Input/Output module offers a compact DIN rail mounted I/O expansion capability for all Trio Motion Coordinators. Up

CAN IO – 16-in Digital (P318)

The Trio CAN16 Input module offers a compact DIN rail mounted output expansion capability for all Trio Motion Coordinators. Up

CAN IO – 16-out Digital (P317)

The Trio CAN16 Output module offers a compact DIN rail mounted output expansion capability for all Trio Motion Coordinators. Up